Blueprint Reading Training

Blueprint Reading Skills Put Your Team on the Same Page.

Blueprint Reading Skills Put Your Team on the Same Page.

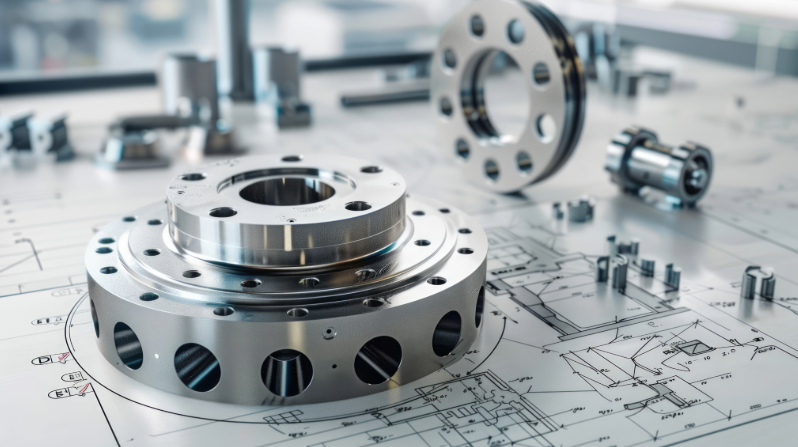

A blueprint is the “page” that contains the plan on how to make a part or a complete product, including critical details on tolerances and specifications. Also known as technical drawings, specification drawings or simply drawings, blueprints are the detailed instructions that help your team consistently produce high quality products that are on spec, with increased efficiency and minimized waste. The more eyes you have that can read blueprints, the more eyes you have on maintaining quality and efficiency, and the greater your profitability.

Blueprint Reading Training

Blueprints and drawings use a lexicon of terms and symbols all their own, and it requires training for people to understand what they mean and how they all fit together. Instead of assuming people can pick up what they need to know along the way, it makes sense to provide formal blueprint reading training to assure everyone in your team is on the same page, and able to read and understand that page. Missouri Enterprise provides Blueprint Reading training classes to teach your key team members the fundamentals of these important documents

Who Needs to Understand Blueprints at Your Manufacturing Facility?

Training your key development and production people how to read blueprints can add tremendous value in terms of quality and efficiency. Impact Dakota’s blueprint reading course will teach your team members what they need to know so everyone can read from the same page effectively. Key team members who will benefit from blueprint reading skills include:

- Product Designers who are well versed on blueprint design can more clearly communicate intent on to drawings that will be used throughout the manufacturing process. Blueprint skilled designers utilize correct ANSI drafting standards (The American National Standards Institute) to improve detail and accuracy in critical areas such as tolerances, bill of materials documentation, part revisions and more.

- Quality Inspectors / Engineers should understand blueprints so they can accurately understand details critical to effectively inspect production parts, identify defects and provide constructive feedback on product variations.

- Manufacturing Engineers with blueprint reading skills can more effectively review drawings to make them better at tasks such as ordering correct production equipment, understanding drafting tolerances and datum structures, design tooling and holding fixtures, documentation of facility layouts, reviewing construction prints for new production lines or plant expansions and more.

- Estimators / Quote Producers need blueprint skills to provide correct, accurate quotes, improve their efficiency and ensure quotes are aligned with production needs like advance verification of possible production issues, understanding material callouts and verification that the company can produce given parts internally, or if there is a need to outsource certain process steps.

- Machinists, Fabricators and Maintenance Personnel on the front line of production are often best positioned to identify problems and make adjustments to improve efficiency and quality. When these people understand blueprints, they’re far better prepared to perform their duties and clearly communicate when changes are needed. Blueprint reading skills help these team members understand machine fixtures and replacement parts that meet drawing requirements, identify correct part features (threads, surface finish, countersinks, keyways, etc.), analyze plant layout drawings for moving equipment or troubleshooting, meet dimension tolerances, clearly follow assembly instructions and more.

Reach out to one of our Senior Business Advisors for information or to schedule Blueprint Reading that works around your production schedule.